Digs projects

Shop Build 52 Chevy 3100

This 1952 Chevy 3100 pickup build came about when Owners Craig and Alan decided it was time for the shop to build a classic automobile that they could display for the 2023 season. They knew it had to be an iconic vehicle most hotrodders could relate to from their past, yet still have that timeless style, design, and popularity to appeal to the next generation of hot rod enthusiasts. While contemplating what to build, an ad was posted for this ‘52 “project” truck that had never been finished. After a short road trip south with the truck and trailer they returned with the bones for their build.

This 1952 Chevy 3100 pickup build came about when Owners Craig and Alan decided it was time for the shop to build a classic automobile that they could display for the 2023 season. They knew it had to be an iconic vehicle most hotrodders could relate to from their past, yet still have that timeless style, design, and popularity to appeal to the next generation of hot rod enthusiasts. While contemplating what to build, an ad was posted for this ‘52 “project” truck that had never been finished. After a short road trip south with the truck and trailer they returned with the bones for their build.

Now that the choice of vehicle was sorted out, planning could begin. With the opportunity to build their own truck, the Dig’s team created a vision and developed the strategy to make it a reality. Knowing they wanted to use the industry’s best components and add some custom touches of their own, the orders were placed. Having the right stance, corning performance, and stopping capabilities, it was a unanimous decision to use an Art Morrison chassis designed specifically for the ‘47-‘53 Chevy 3100 pickup. Outfitted with a 4-link rear suspension, independent front, and Strange coil overs, this truck has the ride and performance Craig and Alan required. To get the wheels spinning on this pickup truck, Dig’s looked to Blueprint Engines for their horsepower solution. This ‘52 features Blueprint Engines’ stroked 427-cubic inch LS style engine that produces 630 hp. Power flows through a Gearstar 4L60E automatic transmission to the 3.50 posi 9” Strange rearend built to handle the torque of the BPE. Dig’s relies on the performance and safety of Wilwood’s 4-wheel disc brake kit to get this custom truck to stop at a moment’s notice. Along with the Wilwood’s, a push button E-Stopp electronic emergency brake was installed.

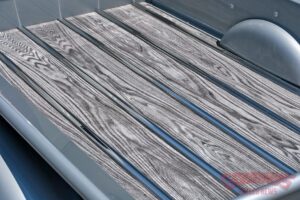

The truck cab and body had the typical rust you would expect to see on a vehicle of its age; however, the repairs and custom fabrication are anything but typical. The Dig’s Fabrication team designed and installed a custom recessed firewall to make room for the engine. The floor has been replaced, cab corners, kick panels, and door bottoms were all repaired. Both side vents and cowl vents were deleted and smoothed. The original bed sides had already been modified to the point we had to start fresh so Dig’s, being a custom shop used the CNC plasma table to cut out and hand build a completely new box kit from 16-gauge steel. Building the box in house gave them the opportunity to bend new cross sills that would raise the Smokey Road Rod Shop extruded aluminum floor kit the 2 inches it needs for clearance with the AME chassis. To close the bed, they went with a MAR-K hidden latch tailgate kit. The final touch for the box is a custom-built roll pan with recessed license plate and relocated LED taillights. The ‘52 has a rear-mounted fuel tank with an in-tank fuel pump that supplies the BPE through Fragola 6000 Series PTFE line and 100% AN fittings. The fuel fill door has been relocated to the driver’s rear fender. The Body and Paint department laid down this elegant Cortez Silver Metallic inside, outside, and painted the AME chassis to match.

They gave the interior of this 3100 a few subtle and functional tweaks as well. An under-dash extension panel hand made from 16 ga. steel added the much need space to mount the push button start, wiper switch, Vintage Air A/C controls and vents. Keeping tabs on the engine vitals and MPH is the Classic Instruments gauge package. The Kenwood Echelon Series 7” Touch Screen CD/DVD Player is dash-mounted and is complemented with a 1600-watt Kenwood amplifier. It has 6” speakers mounted in the custom built and wrapped kick panels up front and 2 more behind the seat and a 10” subwoofer that really rocks. An IDIDIT tilt column, cruise control, a Billet Specialties half Wrapped steering wheel, and power windows provide just the right number of modern amenities for this resto mod. The Wise Guys seat and interior pieces are wrapped in a deep Oxford Wine with matching German square weave carpet and custom floor mats. Wanting to keep the firewall clean and smooth, Dig’s opted to mount all the electronics under the tilt bottom seat with easy access.

This shop build took the better part of a year to complete once the vision was created. Craig and Alan are extremely pleased with the final product and thankful for all the industry connections that this one made. The Dig’s team enjoy working in the hotrod community with the best quality products and inspiration worldwide. Craig and Alan are very thankful for the Dig’s crew, teams, and craftsmanship that made this old American icon into the stunning 3100 that it is today.